Choosing the right wear-layer thickness for your LVP flooring is important. It helps protect your floors and keep them looking good. Here is how to pick the best thickness for your needs.

Want to keep your LVP flooring looking great. It all starts with choosing the right wear-layer thickness. Let’s break it down into simple steps to help you find the perfect fit for your space.

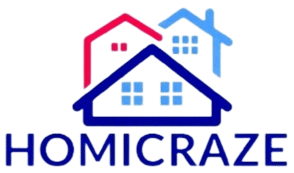

Calculating thickness for vinyl plank floors

Calculating the thickness for vinyl plank floors is simple. First measure the height of the existing flooring or subfloor. Next add the desired thickness of the vinyl plank flooring you want to install.

This total measurement gives you the overall thickness needed for your new floors. Consider factors like door clearance and transitions between rooms when calculating thickness.

Ensure the final thickness allows doors to open and close smoothly without obstruction. By accurately calculating thickness you can ensure a seamless installation process and enjoy beautiful vinyl plank floors in your space.

READ THIS BLOG: THE IMPACT OF FLOORS ON BUYERS AND SELLERS: LVP VS HARDWOOD

Understanding the wear-layer

The wear-layer is a crucial component of vinyl flooring. It is a protective coating that sits on top of the vinyl plank, shielding it from scratches, stains and fading. Thicker wear-layers offer more durability while thinner ones are suitable for low traffic areas.

When choosing vinyl flooring pay attention to the wear-layer thickness. A thicker wear-layer provides better protection against wear and tear making your floors last longer. The wear-layer helps you make an informed decision when selecting vinyl flooring for your home or commercial space.

The role of cores and bottom layers

The cores and bottom layers of vinyl flooring play essential roles in its durability and stability. The core provides structural support and resilience while the bottom layers enhance stability and moisture resistance.

It core material whether it’s WPC (Wood Plastic Composite) or SPC (Stone Plastic Composite), determines the flooring’s overall strength and ability to withstand impact. Cores contribute to the flooring’s resistance to expansion and contraction due to temperature changes.

Bottom layers often made of foam or cork provide additional stability and sound absorption. They also serve as a moisture barrier protecting the subfloor from water damage.

Wear-Layer vs Overall Thickness of LVP – Why it’s important?

The wear-layer and overall thickness of LVP are both crucial factors for flooring durability. The wear-layer positioned on top shields the floor from scratches and wear. While the overall thickness impacts stability and comfort.

It’s the wear-layer that truly determines durability. Opting for a thicker wear-layer ensures your LVP can withstand daily use and maintain its appearance longer regardless of the overall thickness.

What’s A Wear-Layer And Why This Luxury Vinyl Flooring Feature Matters Most

A wear-layer is like a shield for your vinyl flooring. It is a protective coating that sits on top guarding against scratches and scuffs. Think of it as armor for your floors.

This layer matters a lot because it keeps your flooring looking new for longer. Without it every little scratch could show up making your floors look worn out quickly. So, the wear-layer is essential for maintaining that fresh clean look in your home.

Choosing vinyl flooring with a good wear-layer means less worry about damage from everyday activities. It’s like having a built in defense system for your floors ensuring they stay beautiful and durable for years to come.

The Wear-Layer Materials

The wear-layer materials are often made of transparent PVC film. This film acts as a protective barrier against scratches stains and wear. It’s like a shield that keeps your flooring looking new for longer.

These materials are designed to withstand daily use and maintain the appearance of your floors. Some manufacturers may use additional protective overlays. Like Scratch Protect to enhance the wear-layer is performance.

The Wear-Layer Coatings

The wear-layer coatings are applied to the top surface of vinyl flooring. These coatings act as a barrier protecting the underlying layers from scratches stains and fading.

They provide durability and longevity to your floors ensuring they stay looking fresh for years to come. These coatings can vary in thickness and composition depending on the manufacturer and product line.

Some coatings may include additional features like Scratch Protect technology which enhances scratch resistance even further. With these coatings your vinyl flooring is not only beautiful but also resilient against daily wear and tear.

What is a good wear-layer thickness for LVP?

A good wear-layer thickness for LVP is typically around 12 mils. Thicker wear-layers such as 20 mils offer even better protection against scratches and wear. However 12 mils is often sufficient for most residential applications.

For high traffic areas or commercial settings opting for a wear-layer thickness of 20 mils or more is advisable. This provides added durability and ensures the flooring can withstand heavy use without showing signs of wear.

When choosing the best wear-layer thickness for your LVP flooring, consider factors such as foot traffic, pets, and the level of protection required based on your specific needs and preferences.

How thick do you want LVP flooring?

The desired thickness of LVP flooring depends on several factors. For residential use a thickness between 5mm to 8mm is often preferred. Thicker options provide better sound insulation and a more substantial feel underfoot.

In commercial settings or high traffic areas thicker LVP flooring such as 8mm or above. May be preferred for enhanced durability. Thicker planks can better withstand heavy foot traffic and resist wear and tear.

The ideal thickness for LVP flooring depends on your specific needs budget and aesthetic preferences. Consider factors such as the level of foot traffic subfloor conditions and desired comfort level when selecting the appropriate thickness for your space.

How do I choose a quality LVP floor?

Choosing a quality LVP floor involves considering several key factors:

Wear-Layer Thickness

Look for LVP with a durable wear-layer typically around 12 mils or more for residential use and 20 mils or more for commercial settings.

Core Material

Opt for LVP with a high quality core material such as WPC (Wood Plastic Composite) or SPC (Stone Plastic Composite), for added stability and durability.

Appearance and Realism

Select LVP that mimics the look and feel of real hardwood or stone for a more authentic appearance. Pay attention to details like texture, grain patterns and color variation.

Waterproof Properties

Choose waterproof LVP to ensure resistance against spills, moisture and humidity. Making it suitable for areas prone to moisture exposure like kitchens, bathrooms and basements.

Installation Method

Consider the ease of installation and compatibility with your subfloor. Choose LVP with a click lock or glue down installation system based on your preference and the condition of your subfloor.

Brand Reputation

Research reputable brands known for producing high quality LVP flooring with warranties and customer support. Read reviews and testimonials to gauge customer satisfaction and product performance.

Certifications and Standards

Look for LVP that meets industry standards and certifications for indoor air quality, emissions and sustainability ensuring a safe and eco friendly flooring option.

Final Thoughts

Choosing the right thickness of wear-layer for your LVP floors is very important. It helps protect your floors from damage and keeps them looking great. Thicker wear-layers can last longer and provide better protection.You should also consider how the flooring will transition between rooms and doors to make sure everything looks smooth.

For residential areas, wear-layers of 5mm to 8mm thickness are recommended. Commercial spaces may require wear-layers of 8mm or more for added toughness. You should choose the wear-layer thickness that best suits your space. The wear-layer works like a shield, protecting your floors from scratches and scuffs to keep them fresh and clean.

In order to make sure your floors are durable, look for LVP floors with wear-layers of 12 mils or more for homes and 20 mils or more for businesses. By choosing wisely, you can enjoy beautiful and long-lasting floors.

Frequently Asked Questions

What is the ideal wear-layer thickness for LVP flooring?

Around 12 mils for residential use and 20 mils or more for commercial settings.

How do I determine the quality of the core material in LVP flooring?

Look for high quality materials like WPC (Wood Plastic Composite) or SPC (Stone Plastic Composite) for enhanced stability and durability.

Is waterproof LVP necessary for all applications?

No, it depends on the area of installation waterproof LVP is ideal for moisture prone areas like kitchens and bathrooms.

What installation method should I choose for LVP flooring?

Choose between click lock and glue down systems based on subfloor condition and personal preference.